Warning: Undefined array key 1 in /var/www/wp-content/plugins/monarch/monarch.php on line 4359

By Glenn Baja

Up goes the rear slider. Boxes begin rolling, tumbling, and avalanching their way down to the ground. Inside, it’s nothing but boxes, as far back as the eye can see. The Amazon unloading crew, known as the sort team, begins picking up boxes and setting them on their own movable track that butts-up to the trucks stationary conveyer track that runs the entire length of the trailer to be unloaded.

The experience of this seasonal Amazon worker now begins.

The trucks, most often from Fed Ex, UPS, or USPS, contain 3,000 to 4,000 packages, all needing to be scanned, checked in, opened, sorted, and expedited to the appropriate receive line.

It’s a monumental 4-6 hour job that requires a team of 6-8 people. Each person systematically takes a set position and the process begins. One begins unloading boxes onto the conveyer, slowly working over the hours towards the back of the truck, carefully picking boxes in a “pick-up-sticks” sort of manner so others don’t tumble down on top of them. This is important since the logic of loading the heaviest boxes on the bottom with the lightest on top isn’t used. The last thing you want is to have a 50 pound box bonk you on the head or land on your foot.

The next person hand scans every box label, checking each into the Amazon fulfillment center. This is the beginning of the tracking process for every product sent to Amazon.

After the scanner I’m the next man in line. My job is to open each box (and often the boxes within), dispose of any packing materials, be it paper wrap, styrofoam peanuts, air pillows, or someone’s Sunday newspaper, and expose the products so the next person in line can scan it. This scan tells which receive line to place the product on; small, medium, LP (licensed products that have the same product throughout the box), or the prep line, where certain pre-arranged directions are followed be it bubble wrapping, bagging, x-stickering, placing suffocation warning labels inside, or black-bagging x-rated products.

The last positions on the sort team are the people who send the boxed products down the appropriate lines. At the end of each line is 8-14 manned stations where individuals remove the products and then dispose of the boxes on the central overhead conveyer leading to a central compactor. These receivers then scan, separate like items, and count all products, placing them on 30 x 48 inch 3-tiered “totes” on wheels that stand belly button high. These totes, once filled, get scanned, closed out, and moved to an area where the Stow Department of Amazon wheels them away and finds a temporary home for the products in the warehouse until the “pickers” pick them later once orders are placed.

The line moves quickly, the boxes never seem to stop. The tools needed are work gloves, a box cutter, brute strength, and stamina. Not only do your hands tire but you’re on your feet the entire time. There are no chairs to sit in for a quick rest.

Slice after slice, cut after cut… I do battle with the stubborn packaging tape that binds every box. At times the tape seems stronger than I… unforgiving, holding on like rubber-bands, refusing to let go of it’s familiar home. The only recourse is to jerk-tug it harder. If that fails, it’s time to cut again.

I’m conscious of the speed and robotic motions I must use to keep up. The mini-battles with tape slows the process down. Nothing moves forward until I finish my job. Go too slow and the loader runs out of room on the conveyer, or the workers after you end up waiting.

Disposing of the packing materials also chews up time. Some of those endless pillow chains and paper wrap encircle the goods multiple times. It’s similar to pulling a rope out of a box, hand by hand, often dragging the extended chain behind me on the way to the trash bin.

The styrofoam peanuts drive me nuts. They spill all over the floor and the static electricity makes them stick to your gloves and clothing. The fastest and quickest way (but not the cleanest) is to dig in, take the product(s) out, empty the box of these nuances, and put the products back in.

Wanting to do a good job and not be seen as a weak-link in the eyes of the workers who do this for a living, I bust-ass. I become robot-like in motion. One package after another comes. Hours pass. There’s no time to daydream or rest.

My fingertips and hands get sore from the repetition. The muscles in my palms and arms get a work-out they’re not accustomed to. Methodically we work, creating a rhythm and system that quickly gets the job done.

Amazon

At this time of year, everyone is on mandatory overtime at Amazon, a condition all seasonal Workampers agreed to prior to being hired. We work 50 hours in five days, starting at 6 am and finishing at 4:30. If desired, the option to work an additional 5 or 10 hour day is available.

We have two paid 15 minute breaks, one at 8:30 and 1:30, and one unpaid half-hour off for lunch at 10:30. It’s a 4 minute walk to and from the lunch room in this massive building.

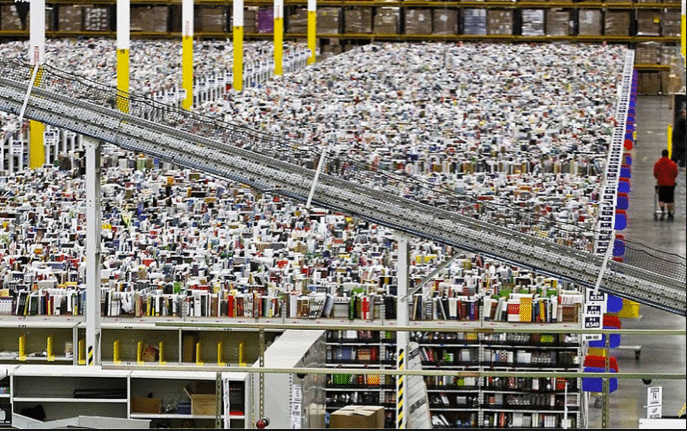

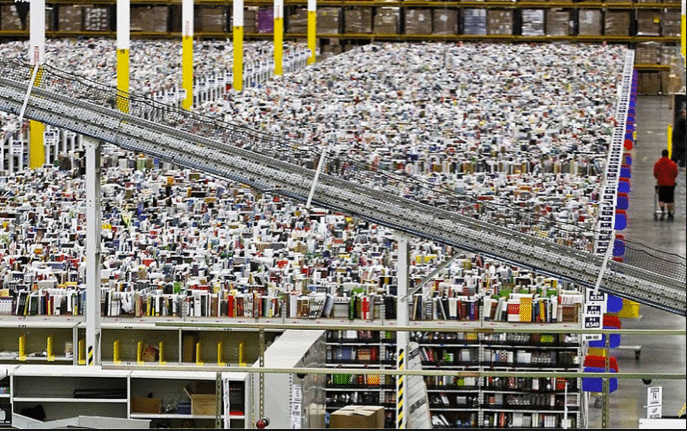

The size of this fulfillment center is astounding. The outside of the building measures over 2/10 mile by 1/10 mile. The walls must be 60-80 foot high. Some parts of the building have four floors. Certain stow areas for pallets have seven levels of shelving. We were told on orientation day that if all floors were laid out on one level the building would be over 2 million square feet.

And this is one of their oldest and smallest facilities.

In the Receive Department where I work I’ve labored on three of the four specialized receive lines. Besides unloading trucks (the sort team), I’ve worked the receiving stations, and recently became a PG, which is a problem solver. As a PG I provide solutions to basic problems receivers may have as well as moving filled totes to the staging area for stowers to pick up. Sometimes it involves something as simple as moving small products found in boxes on the medium line over to the small line. Other times it may be more involved, requiring us to take products to the QA Department (questions/answers) to get special sticking or have unique problems addressed.

The job involves moving constantly on your feet. Registering over 14 miles of walking per day is not unusual. By the end of the day I’m thoroughly beat, tired, and ready to go home.

The Daily Routine

Each work day for Lezlie and I starts at 4 am. I take the first hour to work-out and shower. By 5:30 we’re on the road. Recently I’ve had to cut back on the cardio part of the 4 am workouts since I’m already getting that in during the work day. Doing both was too much.

We’re in bed by 9 or 10 pm. Knowing this is a seasonal job makes this grueling work tolerable. It’s hard work but the experience has been well worth it. We’ve met really interesting people who are living their dream of traveling the country and experiencing life on their terms. Some do it to to make money, some do it to keep themselves busy, and some do it because they love having new experiences.

Amazon likes having Workampers as employees. A human resource employee shared that, on average, every workamper equals three temp workers they get from area agencies. The older workers know how to work and are dependable. Some we’ve met are working at Amazon for their 3rd consecutive season. Many are doing this for their first time.

A week or so ago we met the gal who started the successful Amazon Workampers program. My first question asked was how many drop out on average each season. The answer? 30%. Thirty-percent drop out on average each season for various reasons, yet they still do what they can to attract all the campers they can.

Besides knowing how to work, we show up on time, and don’t complain. At least not too often.

Did you enjoy this post? Please share it with others!

[purehtml id=1]

I’m a self-professed madman, adventurer, photographer, certified High-Performance Coach, martial artist, and licensed physical trainer specializing in senior fitness. My passion is to continue growing and developing into my own unique, gifted, and joyful authenticity, while committing myself towards doing my own special part to help change the world. My mission is to help others find their own direction and purpose in life, by means of mentoring, teaching, and empowering.